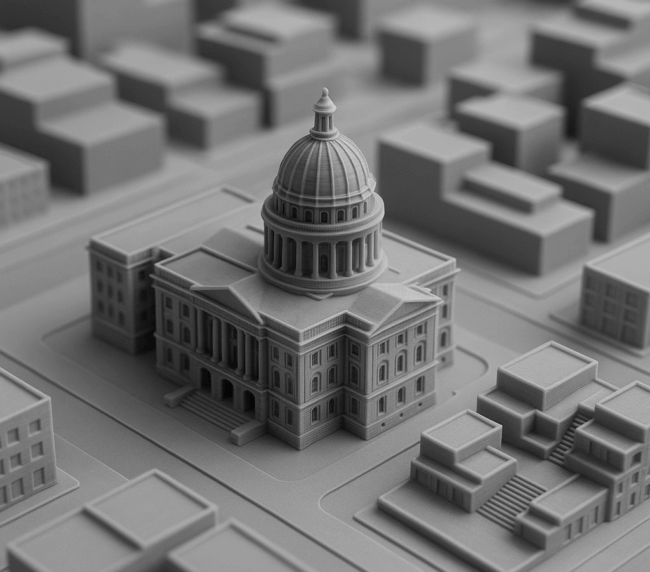

Built for Precision, Trusted for Quality

High-Precision 3D Printing

Tailored Solutions

Versatile Material Range

Rapid Turnaround

Start an amazing journey to startup

Sed ut perspiciatis unde omnis iste natus ut perspic iatis unde omnis iste perspiciatis ut perspiciatis unde omnis iste natus.

- Adipiscing eli sed eiusmod

- Tempor incididunt

- Labore et dolore magna

Your Vision,

Our Expertise

We offer a wide range of 3D printing services, from rapid prototyping to high-volume production, tailored to meet your specific business needs.

- Design

- Mass Production

- Print On Demand

ICO token products

The Numbers Define Our Excellence

Successfully delivered over 100 complex and custom 3D printing projects across various industries, ensuring precision, durability, and quality.

With over a decade of expertise in 3D printing, design, and mass production, we’ve consistently pushed the boundaries of innovation and manufacturing excellence.

We’ve served and satisfied over 2500+ customers, helping businesses transform their ideas into high-quality, functional 3D-printed products.

Our commitment to exceptional service and high-quality output has earned us the trust of 256+ happy clients, helping them scale their production with 3D printing solutions.

Pioneering Excellence in 3D Printing

At CRAV3D, we specialize in high-precision 3D printing, offering customized solutions for prototyping, mass production, and on-demand manufacturing.

Frequently Asked Questions

How many parts can be mass-produced through 3D printing?

3D printing offers a cost-effective and scalable solution for mass production, accommodating small to large production runs ranging from 100 to 500,000 units. With optimized design and production strategies, 3D printing can effectively serve as an alternative to traditional injection molding, even for volumes reaching into the millions, without compromising quality or precision.

Do you provide prototyping services?

Yes, we offer high-quality prototyping services to help you test and refine your product design before moving to large-scale production. Our standard prototyping service uses optimized print settings and materials, ensuring a quick turnaround. Additionally, our team can assist with design modifications to enhance the performance, durability, and manufacturability of your product.

Is 3D printing more cost-effective than injection molding?

In most cases, 3D printing is significantly more cost-effective than traditional injection molding for low to mid-volume production, typically up to 250,000 parts. It eliminates upfront tooling costs and minimizes lead times, allowing faster production and delivery. Additionally, 3D printing offers greater design flexibility, enabling quick adjustments without heavy financial investments. However, cost-effectiveness may vary depending on the complexity and scale of the project.

What types of materials do you use for 3D printing?

At CRAV3D, we offer a wide range of high-quality materials to suit various industrial applications. Our material options include heat-resistant, durable, flexible, and high-strength plastics, allowing us to produce functional parts, prototypes, and large-scale production components. Depending on your project requirements, we can recommend the most suitable material to ensure optimal performance, durability, and cost-efficiency.

Latest Stories